Self-balancing Horizontal Multistage Centrifugal Pump

New structure, wide application range

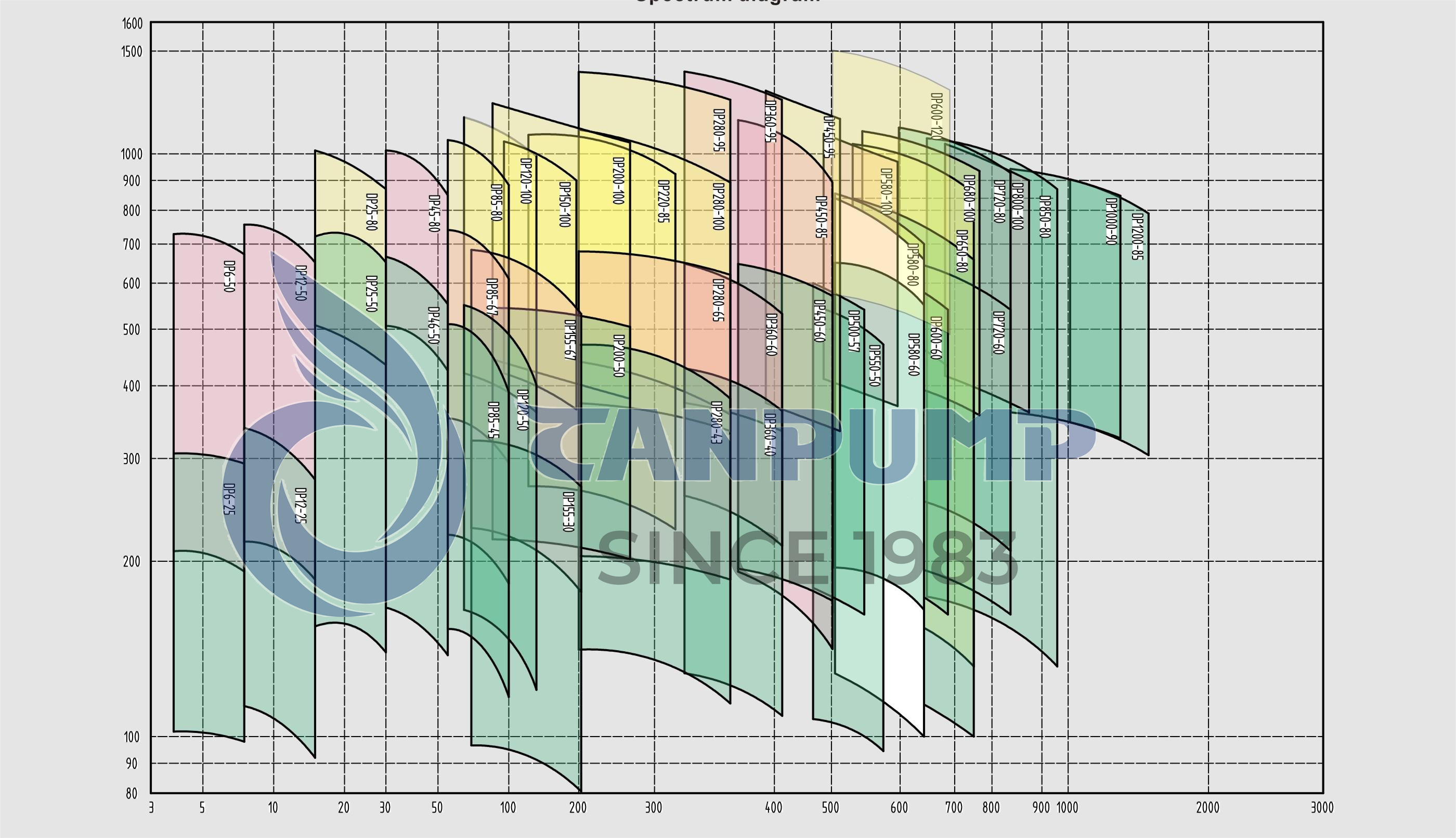

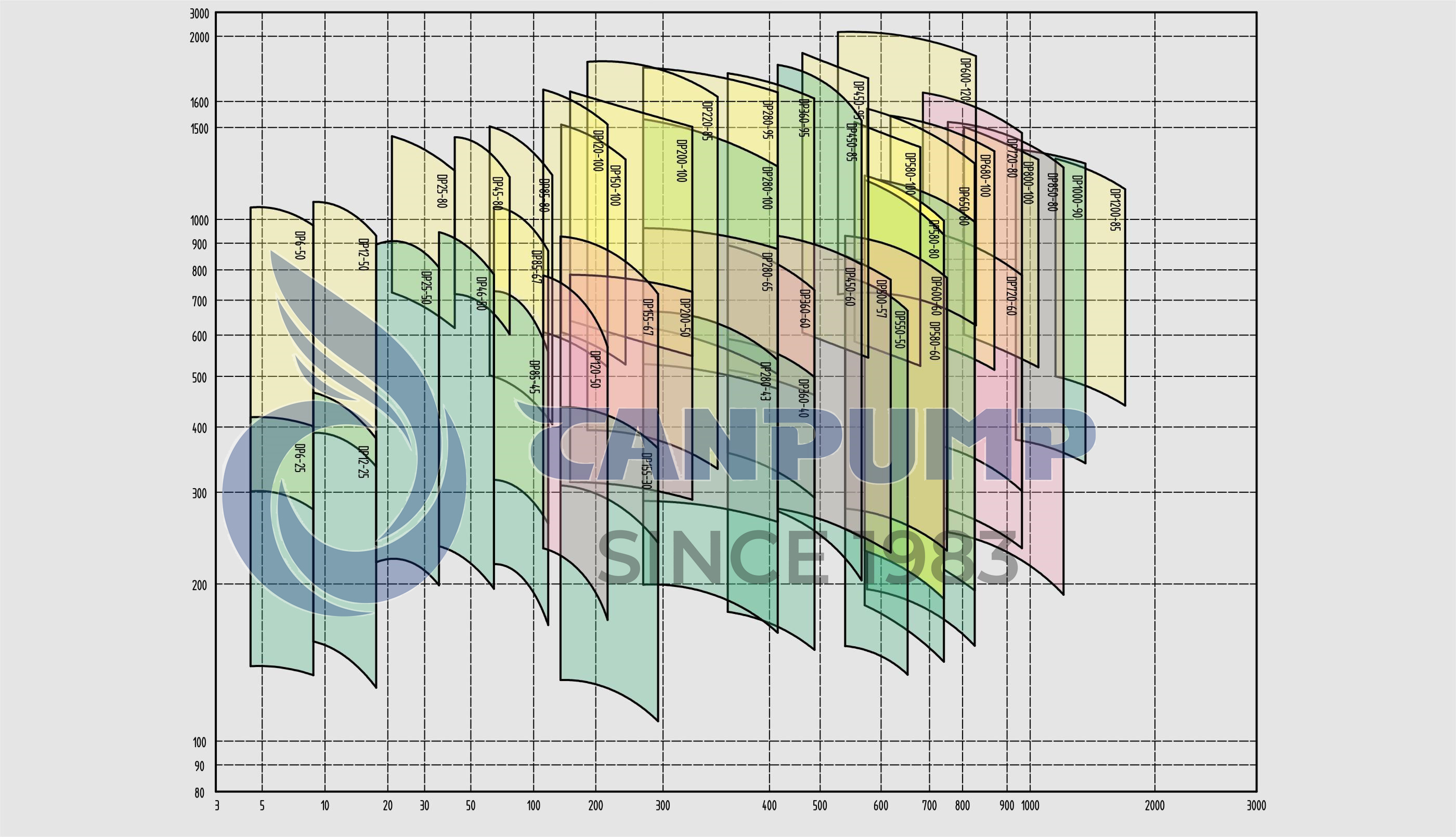

TECHNICAL DATA

DN: 40-350mm

Flow: 3.75-1360m3/h

Head: 92-1500m

Motor Power: 7.5-4,000kw

Advantages

New structure

High efficiency and energy conservation

High reliability

High stability

High cavitation resistance

Strong reliability of mechanical seal

Easy maintenance

Low maintenance rate

Strong applicability

Application&Materials

| Model | Applicable media | Texture of material |

| DP | Pure water, below 80℃ | Flow passage parts material: cast iron |

| DFP | Oil, temperature below 80℃,Viscosity less than 120 cSt | Flow passage parts material: cast steel or cast stainless steel based on temperature and causticity of the fluid |

| DYP | Corrosive fluids, -20℃~105℃ | Flow passage parts material: cast iron, cast steel or cast stainless steel based on temperature of the fluid |

| DMP | Fluids with solids ≤1.5%, dia. ≤0.5mm, temperature -20~80℃ | Flow passage material: wear-resistance iron or ductile iron |

Advantages

· New structure

With rotor components with symmetric impellers,the product offsets the axial thrust generated during operation of forward and backward sets of impellers.In this way,the balancing disc device with small clearance and high pressure drop, which is easily flushed,worn and fails is not needed to keep axial force balancing,breaking the traditional structure of multi-stage pump.

· New technology

Unique throttling and pressure relieving device,odd-level balancing device,playing a supporting role.

· High efficiency and energy conservation

Advanced hydraulic model and independently developed high-efficiency energy-saving products are adopted; since the pump rotor doesn't have abrasion of the balancing disc or axial pulse,the impeller and the guide vane are always centered in the optimal way,unike ordinary multi-stage pump whose efficiency drops remarkably with abrasion of the balancing disc and the forward moving ot the rotor component; there is no balancing water leakage,thus reducing the volume loss and improving operation efficiency of the pump on the whole and reducing the axial power. 2%-3% higher than ordinary multi-stage pump in efficiency.

· High reliability

Self-balancing axial force load reduces pump abrasion and system disturbance by the largest extent. A very small portion of residual axial force is borne by the thrust bearing,so that the pump shaft is always tensioned uniformly, and the stress peak is much lower than the original structure, thus improving rotor rigidity and critical rotating speed, and remarkably improving rotor operation stability and reliability.

· High stability

With optimal combination of symmetrical impeller and guide vane,as well as reasonable fitting clearance and wide axial throttling design,the pump can maintain high stability and operation efficiency during long term operation.

· High cavitation resistance

With optimal hydraulic model and structural design,special first-stage impeller dual-suction structure,precise casting and reliable wearing resistance,the pump has sound cavitation resistance. The machine runs stably with low noise.A front pump is not needed and the water tank height doesn’t need to be raised.

· Strong reliability of mechanical seal

When the pump is started or stopped, the rotor component doesn't have axial play.When it's in operation,the rotor component has no axial pulse. The problem of poor reliability of mechanical seal which has troubled the multi-stage pump for long has been overcome.

· Easy maintenance

With rapid assembly & disassembly design,the pump is allowed to change seal and bearing without dismantling the pump body and inlet/outlet pipelines.There are no wearing parts such as balancing disc in the pump,thus saving time for overhauling and inspection.

· Low maintenance rate

Precise casting is adopted,thus reducing wearing components and times of maintenance and disassembly,extending service life,avoiding problems caused by too many times of disassembling, and lowering the maintenance cost.

· Strong applicability

With advanced modular design,partial components and parts that have been tested by repeated use and long-term operation have high level of interchangeability.

Small-clearance balancing disc device is canceled,more suitable for tough media than multi- stage pumps of conventional structure.

Performance Range

DP 50HZ

DP 60HZ

Other products

*Note: Please be sure to fill in the information accurately, keep the communication open, we will get in touch with you as soon as possible